Wastewater services

We own and maintain more than 21,000 connections and 5,400 access chambers to 350 kilometres of sewers, which handle a volume of 4,700 million litres per year.

Our role is to:

- provide reliable, affordable and environmentally acceptable wastewater collection and disposal systems for the urban communities

- ensure that these systems protect public health and safety as well as the environment, and that they are adequate to meet present and future needs.

We use a computerised monitoring and control system to manage all treatment plants and pumping stations, except for very small pump stations and those with very high storage capacities, which are monitored manually. All major pump stations have emergency standby generators.

Ōtaki

Ōtaki is served by 31 sewage pumping stations that discharge water into the Ōtaki Wastewater Treatment Plant.

Capacity

The Ōtaki Wastewater Treatment Plant serves an estimated population of 6,000 and also treats wastewater from local commercial and industrial facilities. The plant was upgraded in 1997 and it is designed to serve a population equivalent of 12,600, which on the projection forecast, would be reached about 2011.

Process

The Ōtaki Wastewater Treatment Plant provides preliminary and secondary treatment based on an oxidation pond system with two ponds in parallel preceded by screening and an aerated lagoon. The purpose is to reduce the contaminant to an acceptable level prior to disposal by infiltration to land with no discharge to surface waters. During 1997 a primary clarifier and was added to the process.

Components are:

- pre-treatment (1.5 millimetres Contra-Shear Milliscreen)

- aerated lagoon (approximately 2000 cubic metres)

- clarifier

- primary sludge treatment by NX4000 decanter to 6 percent then to Paraparaumu wastewater treatment plant

- oxidation ponds (total 4.14 hectares)

- land disposal treatment area (10.9 hectares divided into 6 plots, each with 3 cells).

Desludging

Between April and late October 2022, the oxidation ponds at the Ōtaki Wastewater Treatment Plant are being desludged. Depending on weather conditions and what’s in the sludge, this work might cause unusual smells in the area. The sludge and solids will be transported to an approved landfill.

As part of their natural process, oxidation ponds form a sludge layer at the bottom, where solids accumulate and are digested. The sludge needs to be removed every 5-10 years to ensure oxidation ponds keep working efficiently.

We’ll try to minimise smells and we thank people for their patience during this work.

Upgrades

Major upgrades were commissioned during 1997. These included a 12 m diameter clarifier, together with associated pipework, valves, pumps and weirs. The level of the oxidation ponds was raised by some 150mm thus increasing the total retention time, and new outlet screens installed.

The land disposal treatment area (LDTA) was also upgraded with the surface ripped, new bunds formed, flaxes planted and new distribution pipes installed.

In 2011 primary sludge treatment was upgraded with the install of a primary sludge storage tank and the NX4000 decanter as well a thicken sludge tank and a bio filter for odour control.

In 2015 the effluent storage basin was added, for temporary storm buffering before discharge to the LDTA.

For 2020/21 further upgrades to the LDTA include a pump station refurbishment and upgrade and a new effluent distribution header, with additional flow control automation. There is also planned a planting programme of Harakeke (flax) and Manuka, and a public safety upgrade including new fencing of the LDTA perimeter.

Waikanae/Paraparaumu/Raumati

The communities of Waikanae, Paraparaumu and Raumati are served by a single wastewater treatment plant in Paraparaumu, which was upgraded in 2001/02. At that time the oxidation ponds at Waikanae were closed and all Waikanae wastewater pumped to Paraparaumu for treatment.

There are 15 pumping stations in Waikanae and Paraparaumu and Raumati communities are served by 105 pumping stations. The Paraparaumu Wastewater Treatment Plant operates a Biological Nutrient Removal process, one of the most advanced treatment processes in New Zealand. The plant treats approximately 10 million litres of wastewater every day.

Resource consents were granted for 20 years and expired in March 2022. In December 2021, Council lodged an application with Greater Wellington Regional Council (GW) to renew the resource consents held for the plant. GW agreed Council can continue to operate the plant until a decision is made on the application. Read more about our wastewater treatment plant consenting process.

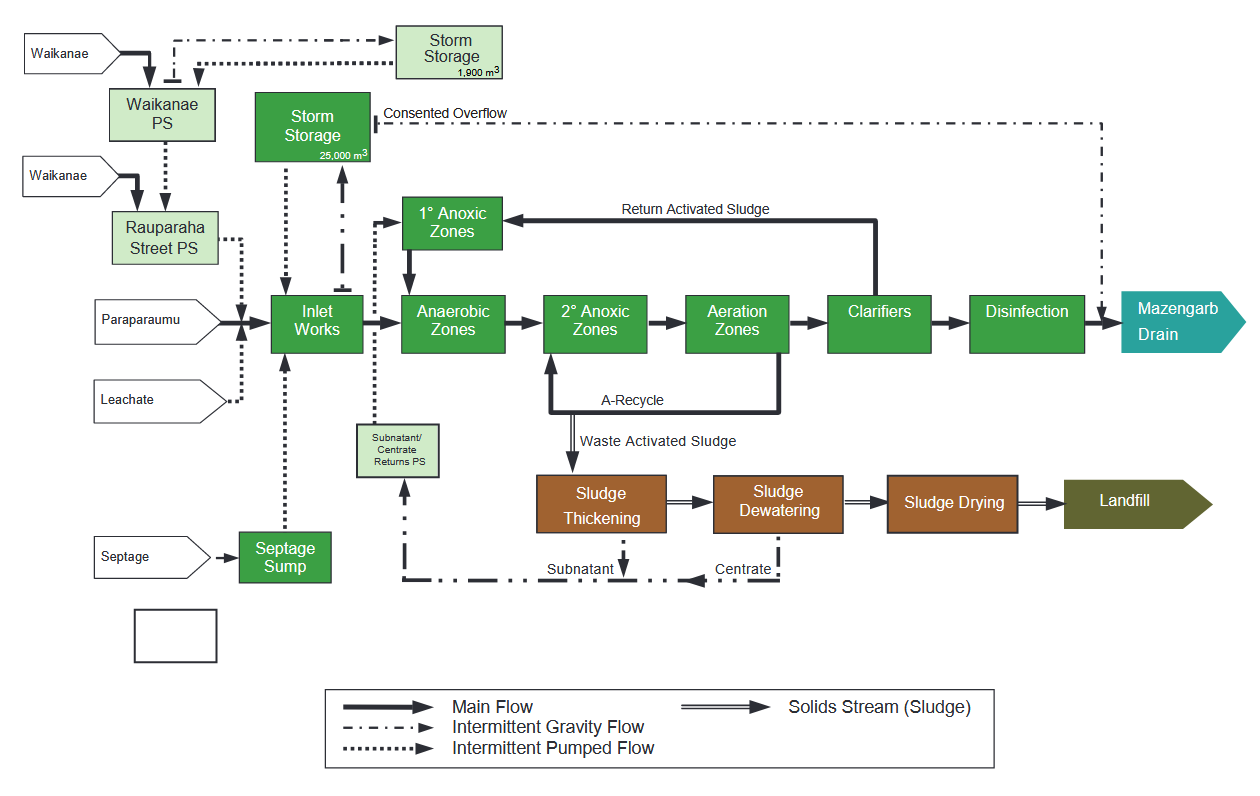

Flow schematic of Paraparaumu wastewater treatment plant and local wastewater network

Planning for the future

We'll need to invest in the Paraparaumu wastewater treatment plant in the coming years to meet the projected growth in the district and renew aging equipment that's been in service since the earlier upgrades. A study was carried out in 2015–17 to assess the condition and capacity of the plant and plan out the works required to maintain its performance now and into the future.

Paekākāriki and rural areas

The community of Paekākāriki uses septic tanks. Rural areas of the district rely on onsite disposal, septic tanks or community package wastewater treatment plants.